Tantalum (Ta)

- All Products

- Tantalum

Overview

Tantalum is a rare, lustrous transition metal known for its distinctive blue-grey hue and exceptional durability. It belongs to Group 5 of the periodic table, has an atomic number of 73, and an atomic weight of 180.94788. Recognized for its outstanding resistance to corrosion and impressive ductility, Tantalum is an essential material in various industries, including electronics, aerospace, medical, and manufacturing.

Its remarkable properties such as high melting point (2,996°C), thermal and electrical conductivity, and biocompatibility make it a versatile choice for demanding applications. Tantalum’s name is derived from the Greek mythological figure “Tantalos,” father of Niobe, due to its historical association with niobium, a closely related element.

Tantalum Properties

- Symbol: Ta

- Atomic Number: 73

- Atomic Weight: 180.94788

- Density: 16.69 g/cm³

- Melting Point: 2,996°C

- Boiling Point: 5,458°C

- Atomic Radius: 143 pm

- Van der Waals Radius: 200 pm

- Electron Configuration: [Xe] 4f¹⁴ 5d³ 6s²

- CAS Number: 7440-25-7

In its elemental form, Tantalum appears as a hard, ductile metal with a beautiful greyish-blue lustre. Its high resistance to heat and corrosion places it among the refractory metals, making it suitable for high-temperature environments and chemically aggressive conditions.

Key Applications of Tantalum

Electronics:

Capacitors and High-Power Resistors: Tantalum is widely used in the production of capacitors due to its excellent dielectric properties. These capacitors are crucial for compact electronic devices such as mobile phones, computers, and automotive electronics, where reliability and high performance are required.

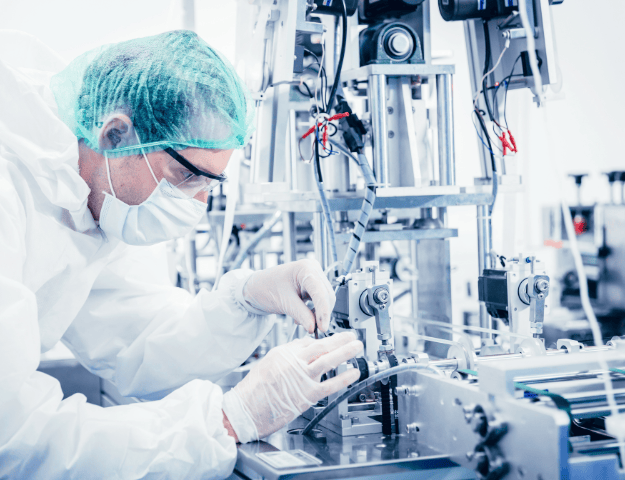

Semiconductor Industry: Tantalum’s properties make it suitable for thin-film applications and as a diffusion barrier in integrated circuits, enhancing the performance of microelectronics.

Medical:

Surgical Implants: Tantalum’s biocompatibility makes it a preferred material for medical implants, such as hip replacements and dental instruments. Its ability to form a stable, protective oxide layer ensures safety and longevity inside the human body.

Surgical Tools and Equipment: The metal is used in various medical tools due to its non-toxic nature and high resistance to wear.

Aerospace and Defence:

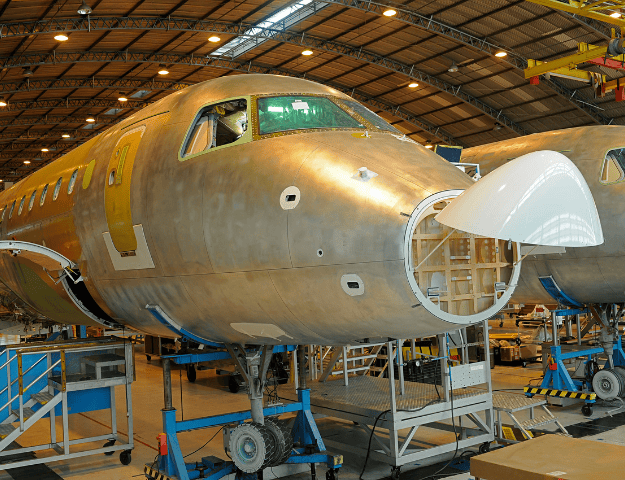

High-Temperature Alloys: Tantalum is alloyed with other refractory metals to produce materials that can withstand extreme temperatures and corrosive environments. These alloys are used in jet engines, rocket components, and protective coatings.

Machining and Cutting Tools: Tantalum carbide is used to manufacture high-speed cutting tools, drills, and milling equipment, offering hardness and wear resistance.

Chemical Processing:

Tantalum’s resistance to acids makes it ideal for chemical processing equipment, such as heat exchangers, reactor vessels, and lining of piping systems, where exposure to highly corrosive substances is common.

Safety Information

Tantalum in its metallic form is considered non-toxic and poses no significant health hazards under normal handling

However, some compounds may have specific safety considerations that should be reviewed before use. When transporting Tantalum products, regulations for hazardous materials may apply, depending on the form (e.g., powders) and the destination. For detailed safety information, refer to Safety Data Sheets (SDS) and comply with local transportation guidelines.

Why Choose Tantalum?

-

Unmatched Corrosion Resistance:

Performs excellently in highly corrosive environments, especially with strong acids.

-

High Melting Point:

Suitable for applications requiring stability at elevated temperatures

-

Biocompatibility:

Ideal for medical implants and devices.

-

Versatility in Forms:

Available in various shapes, sizes, and purity levels to meet diverse industrial needs.

-

Reliable Conductivity:

Efficiently conducts heat and electricity, making it useful in electronics.

Explore Our Tantalum Products

Discover our comprehensive range of Tantalum products and find the perfect material for your next project

Whether you’re working in electronics, aerospace, medical, or chemical industries, our high-quality Tantalum offerings will meet your requirements.

Frequently Asked Question

Marker bands are usually made from radiopaque materials such as platinum, platinum-iridium alloy, tantalum, or gold, which are highly visible on X-rays.

Marker bands are widely used in various medical fields, including cardiology, neurology, urology, and orthopedics. They are particularly helpful in guiding catheters during procedures like angioplasty, deep brain stimulation, kidney stone removal, and implant placement.

Yes, marker bands are generally considered safe and biocompatible. They are designed to be well-tolerated by the body and do not typically cause adverse reactions. However, as with any medical procedure, there may be rare risks associated with their use, such as allergic reactions or migration.